BUTTERFLY VALVES

Hattersley butterfly valves are compact quarter-turn valves with an elastomer-lined body for a tight seal. Available in wafer or lugged designs, they can be operated by lever or gearbox, with linings of EPDM or Nitrile rubber based on service conditions. While primarily for on-off service, they can also handle non-critical throttling. A quarter turn is sufficient to open or close the valve. Hattersley also provides high-performance butterfly valves designed for superior shut-off and regulation, suitable for high pressure and temperature conditions beyond standard concentric disc valves, ensuring exceptional performance and reliability.

Fig. 950 & 950G

Semi-lugged Wafer Pattern Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust ductile iron valve body for long life service

• Valve body semi-lugged to fit PN10, PN16, or Class 125 flanges

• Integrated notch plate for a more compact design

• The anti-blow out stem design provides a safe and secure operation

• Fully bonded epoxy paint system for superior corrosion resistance

• Suitable for applications where Level 3 C3 (Medium) corrosion protection is required

• Maintenance free valve design, reducing downtime

DIMENSIONAL DRAWING

Fig. 950W & 950WG

Semi-lugged Wafer Pattern Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust ductile iron valve body for long life service

• WRAS approved for potable water applications -10°C to 80°C

• Valve body semi-lugged to fit PN10, PN16, or Class 125 flanges

• Integrated notch plate for a more compact design

• The anti-blow out stem design provides a safe and secure operation

• Fully bonded epoxy paint system for superior corrosion resistance

• Suitable for applications where Level 3 C3 (Medium) corrosion protection is required

• Maintenance free valve design, reducing downtime

DIMENSIONAL DRAWING

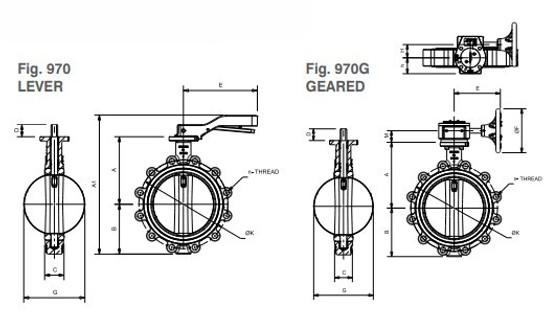

Fig. 970 & 970G

Fully-lugged, Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust ductile iron valve body for long life service

• Integrated notch plate for a more compact design

• The anti-blow out stem design provides a safe and secure operation

• Fully bonded epoxy paint system for superior corrosion resistance

• Suitable for applications where Level 3 C3 (Medium) corrosion protection is required

• Maintenance free valve design, reducing downtime

DIMENSIONAL DRAWING

Fig. 970W & 970WG

Fully-lugged, Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust ductile iron valve body for long life service

• WRAS approved for potable water applications -10°C to 80°C

• Integrated notch plate for a more compact design

• The anti-blow out stem design provides a safe and secure operation

• Fully bonded epoxy paint system for superior corrosion resistance

• Suitable for applications where Level 3 C3 (Medium) corrosion protection is required

• Maintenance free valve design, reducing downtime

DIMENSIONAL DRAWING

Fig. 951 & 951G

Semi-lugged Wafer Pattern Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust ductile iron valve body for long life service

• Valve body semi-lugged to fit PN10, PN16, or Class 125 flanges

• Integrated notch plate for a more compact design

• The anti-blow out stem design provides a safe and secure operation

• Fully bonded epoxy paint system for superior corrosion resistance

• Suitable for applications where Level 3 C3 (Medium) corrosion protection is required

• Maintenance free valve design, reducing downtime

DIMENSIONAL DRAWING

Fig. 971 & 971G

Fully-lugged, Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust ductile iron valve body for long life service

• Integrated notch plate for a more compact design

• The anti-blow out stem design provides a safe and secure operation

• Fully bonded epoxy paint system for superior corrosion resistance

• Suitable for applications where Level 3 C3 (Medium) corrosion protection is required

• Maintenance free valve design, reducing downtime

DIMENSIONAL DRAWING

Fig. 4970 & 4970G

Fully-lugged Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust, ductile Iron valve bodies for long service life

• Stainless steel disc for improved strength and a wide range of applications

• Valve body fully-lugged for secure installation

• Integrated notch plate for a more compact design

• The anti-blow out stem design provides a safe and secure operation

• Fully bonded epoxy paint system for superior corrosion resistance

• Suitable for applications where Level 3 C3 (Medium) corrosion protection is required

• Maintenance free valve design, reducing downtime

DIMENSIONAL DRAWING

Fig. 980 ANSI

Fully-lugged, Lever/Gearbox Operated Class 150

DIMENSIONAL DRAWING

Fig.4925 & Fig.4925G

Fully-lugged, Lever/Gearbox Operated

FEATURES & BENEFITS

• Robust, ductile iron valve bodies for long service life

• Stainless steel disc for improved strength and a wide range of applications

• Suitable for wide temperature range -10°C to 120°C

• Fully lugged for secure installation

• Rated PN25 for higher pressure applications

• Lever (4925) and Gearbox (4925G) options available

• Extended size range for application requirements

DIMENSIONAL DRAWING

Fig. 4930G / 5930G & Fig. 4930BS

Fully-lugged, Gearbox Operated / Bare Shaft

FEATURES & BENEFITS

• Manufactured to BS EN 593: 2009

• Suitable for Gearbox or Actuator operation

• Rugged construction: Ductile Iron Body for all sizes

• Stainless Steel disc for a wide range of applications

• Epoxy paint coated for enhanced durability

• Low operating torques

DIMENSIONAL DRAWING

Fig. 4930G / 5930G ANSI & Fig. 4930BS ANSI

Fully-lugged, Gearbox Operated / Bare Shaft

FEATURES & BENEFITS

• Manufactured to BS EN 593: 2009

• Suitable for Gearbox or Actuator operation

• Rugged construction: Ductile Iron Body for all sizes

• Stainless Steel disc as standard

• Epoxy paint coated as standard

• Low operating torques

DIMENSIONAL DRAWING